Micro-Manufacturing: Revolutionizing Small-Scale Production

Micro-manufacturing is reshaping the industrial landscape, offering unprecedented opportunities for small-scale, localized production. This innovative approach combines cutting-edge technologies with agile manufacturing principles to create highly efficient, adaptable production systems. As businesses seek ways to reduce costs, improve sustainability, and meet evolving consumer demands, micro-manufacturing emerges as a game-changing solution with far-reaching implications for various industries.

Historical Context and Key Developments

Micro-manufacturing can trace its roots back to the early 2000s when researchers began exploring ways to miniaturize manufacturing processes. The initial focus was on creating microscale components for industries such as electronics and medical devices. However, as technology advanced, the scope of micro-manufacturing expanded to encompass a broader range of products and applications.

Key developments that have contributed to the growth of micro-manufacturing include:

-

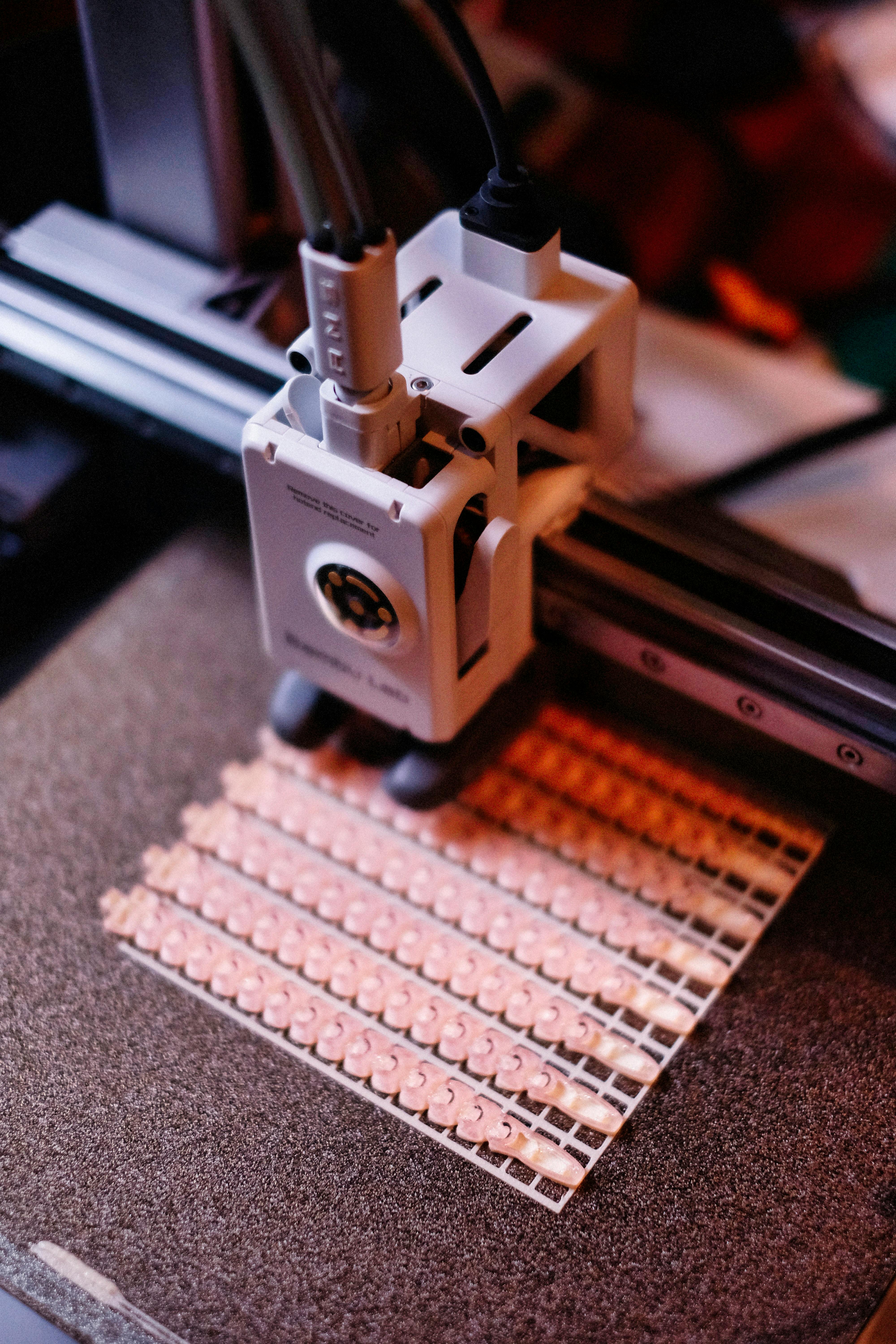

Additive manufacturing (3D printing) technologies

-

Advanced robotics and automation systems

-

Artificial intelligence and machine learning algorithms

-

Internet of Things (IoT) connectivity

-

Improved materials science and nanotechnology

These advancements have collectively enabled the creation of highly efficient, compact manufacturing systems capable of producing a wide variety of products with minimal human intervention.

Current Trends and Expert Insights

Industry experts predict that micro-manufacturing will continue to grow in importance, driven by several key trends:

-

Localized production: As global supply chains face disruptions, businesses are increasingly looking to bring production closer to end-users, reducing transportation costs and improving responsiveness to market demands.

-

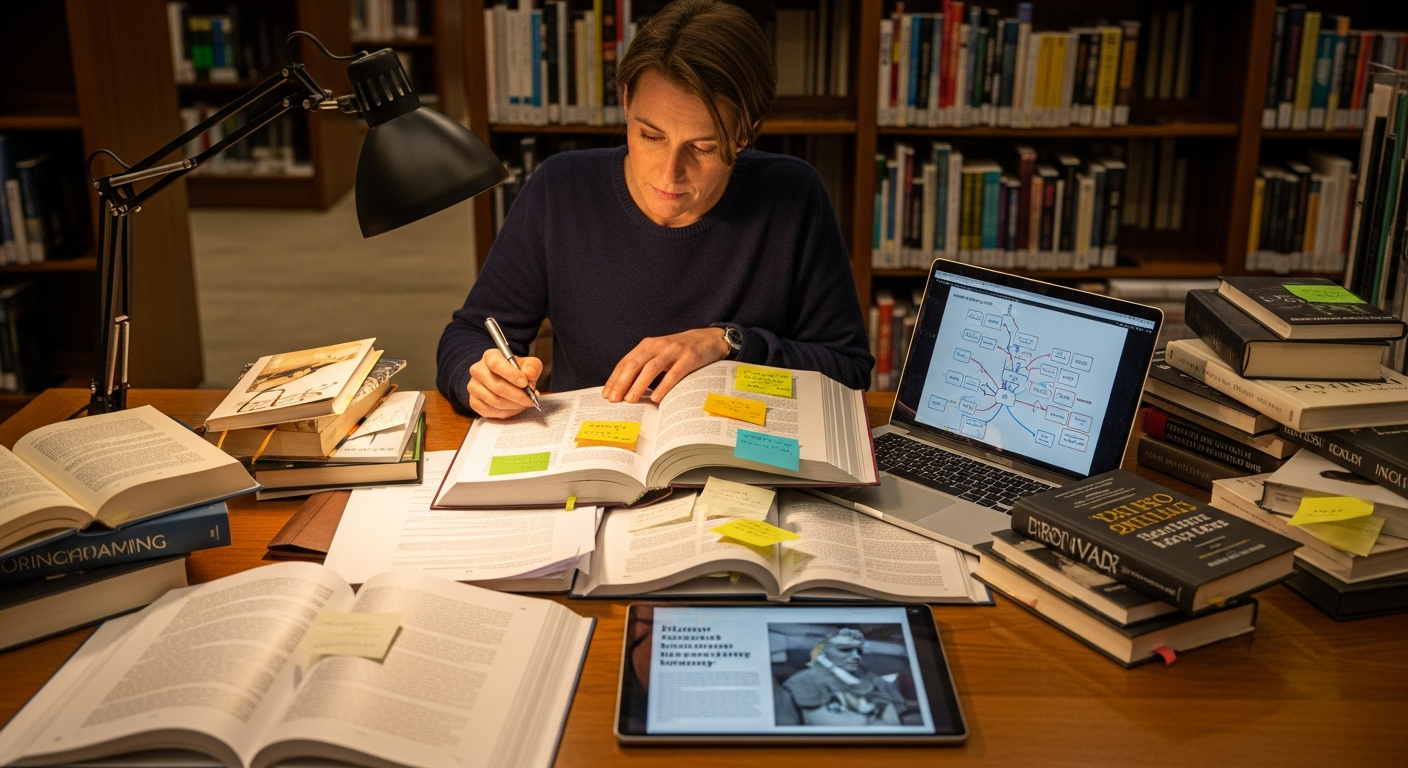

Customization: Consumers are demanding more personalized products, and micro-manufacturing allows for cost-effective small-batch production and rapid prototyping.

-

Sustainability: Smaller, more efficient production facilities can reduce energy consumption and waste, aligning with growing environmental concerns.

-

Democratization of manufacturing: Micro-manufacturing technologies are becoming more accessible, allowing smaller businesses and even individuals to engage in production activities previously limited to large corporations.

-

Integration with digital platforms: E-commerce and on-demand manufacturing are converging, creating new business models and opportunities for entrepreneurs.

Impact on Business and Industry

The rise of micro-manufacturing is having a profound impact on various sectors:

-

Consumer goods: Companies can now offer highly customized products, from personalized clothing to bespoke furniture, at competitive prices.

-

Medical devices: Micro-manufacturing enables the production of complex, patient-specific implants and prosthetics.

-

Electronics: Small-scale production of specialized electronic components and devices becomes more feasible and cost-effective.

-

Automotive: Niche vehicle manufacturers and aftermarket parts producers can leverage micro-manufacturing to create custom components and limited-edition products.

-

Aerospace: Micro-manufacturing facilitates the production of complex, lightweight parts for aircraft and spacecraft.

Benefits and Challenges

Micro-manufacturing offers numerous benefits, including:

-

Reduced capital investment: Smaller production facilities require less upfront investment compared to traditional factories.

-

Increased flexibility: Rapid retooling and reconfiguration allow for quick adaptation to changing market demands.

-

Improved quality control: Smaller batch sizes and advanced monitoring systems enable tighter quality control.

-

Reduced inventory costs: Just-in-time production minimizes the need for large inventory stockpiles.

-

Enhanced innovation: Rapid prototyping and iterative design processes accelerate product development cycles.

However, challenges remain:

-

Skill gap: The workforce needs to be upskilled to operate and maintain advanced micro-manufacturing systems.

-

Initial costs: While overall capital investment may be lower, the per-unit cost of production can be higher for very small batches.

-

Regulatory hurdles: Existing regulations may not be well-suited to the unique characteristics of micro-manufacturing facilities.

-

Supply chain integration: Coordinating multiple small-scale producers can be more complex than managing traditional supply chains.

-

Scalability: As demand grows, transitioning from micro-manufacturing to larger-scale production can be challenging.

Maximizing Micro-Manufacturing Success

• Invest in employee training to build a skilled workforce capable of operating advanced manufacturing systems

• Develop partnerships with technology providers to stay at the forefront of micro-manufacturing innovations

• Implement robust quality control systems to ensure consistency across small-batch productions

• Leverage data analytics to optimize production processes and predict maintenance needs

• Explore collaborative ecosystems with other micro-manufacturers to share resources and expertise

• Consider hybrid models that combine micro-manufacturing with traditional production methods for optimal flexibility

In conclusion, micro-manufacturing represents a paradigm shift in industrial production, offering unprecedented flexibility, customization, and localization. As technology continues to advance and consumer demands evolve, businesses that embrace micro-manufacturing principles will be well-positioned to thrive in an increasingly dynamic and competitive marketplace. By understanding the potential and challenges of this approach, industry leaders can make informed decisions about integrating micro-manufacturing into their operations, potentially unlocking new avenues for growth and innovation.